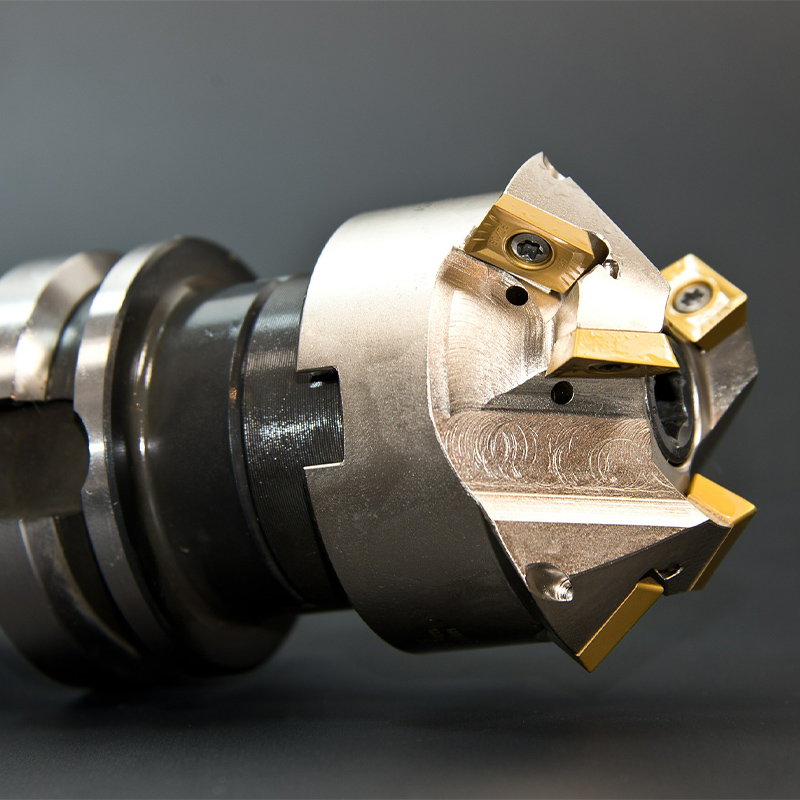

Precision, Stability & Performance

Key Features

High Clamping Stability

Ensures a secure grip on the cutting tool, reducing tool deflection and improving machining accuracy.

Durable & Rigid Construction

Made from hardened alloy steel for superior strength, wear resistance, and longevity.

Precision Balancing

Minimizes vibration and runout, ensuring smooth and efficient milling operations.

Versatile Compatibility

Supports a range of milling cutters, indexable inserts, and end mills.

Optimized for High-Speed Machining

Designed to perform in high RPM conditions without compromising tool stability.

Available in Multiple Configurations

Includes BT, HSK, CAT, SK, and ISO tool holder types for various machine setups.

Applications

Automotive Industry

Precision milling of engine components, transmission parts, and chassis structures.

Aerospace Sector

High-speed machining of aluminum, titanium, and composite materials.

General Engineering & Heavy Machinery

Reliable performance in high-load milling operations.

Mold & Die Manufacturing

Accurate profiling, slotting, and contouring for complex mold structures.